HIGH SPEED PROCESSING

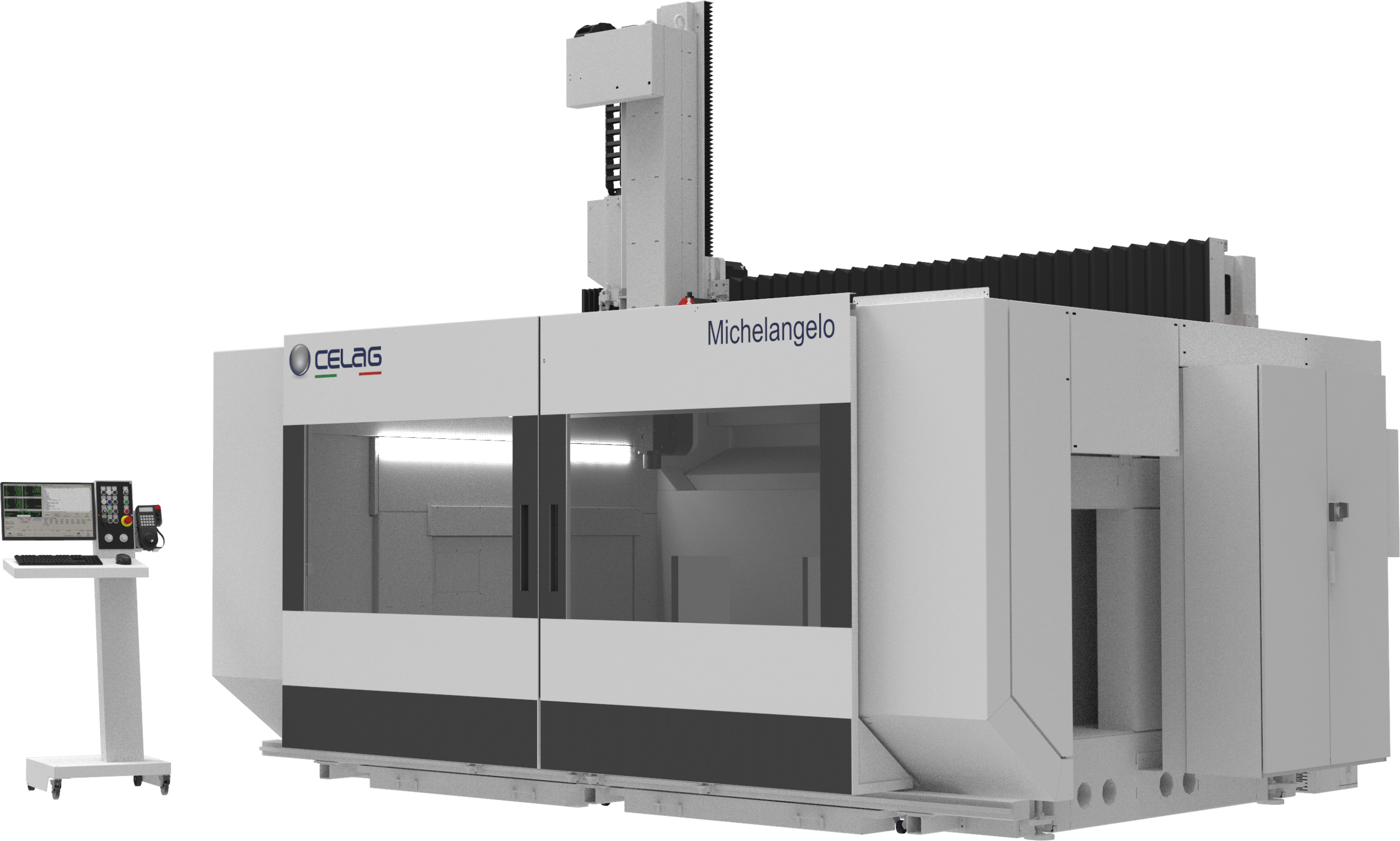

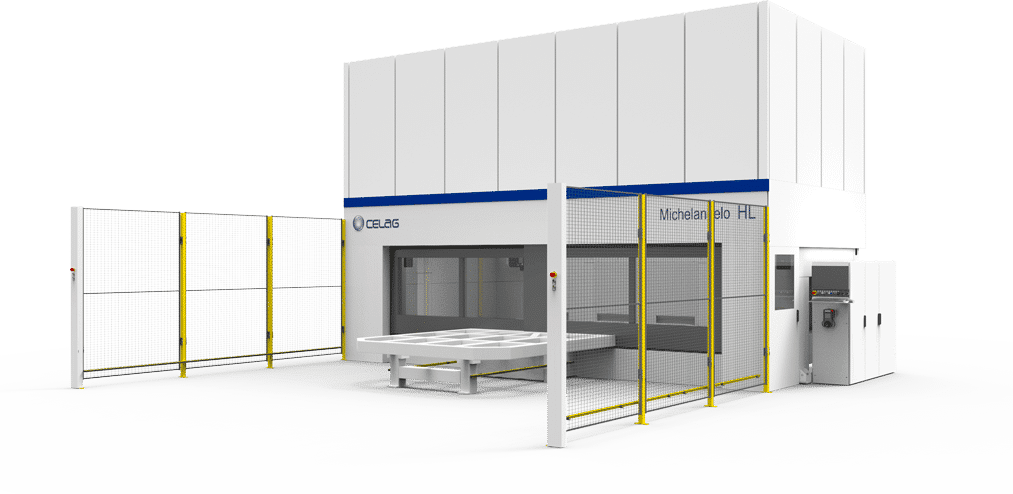

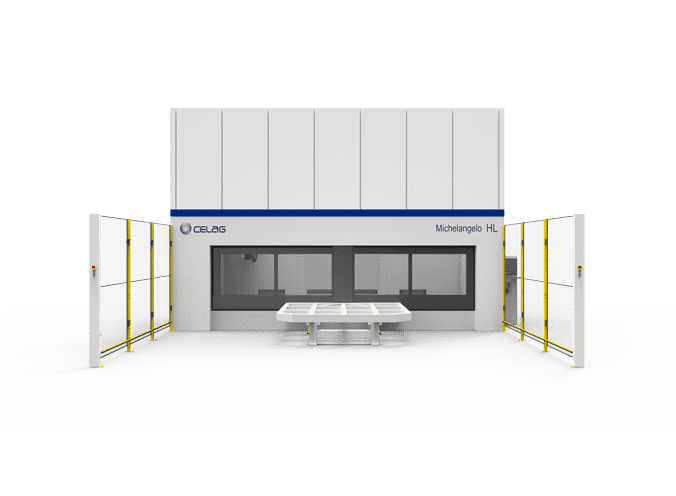

The Michelangelo HL Machining Center with Rotating Table is the ideal solution for high-speed machining on composite materials and is particularly suitable for productions that require the ability to machine many pieces in the shortest possible time.

5-AXIS TECHNOLOGY FOR PROCESSING CARBON FIBER

The rotating table guarantees maximum speed in production processes thanks to the possibility of loading and unloading in masked time

Easy access to the outside of the work area allows you to load even the biggest pieces with great comfort and in total safety.

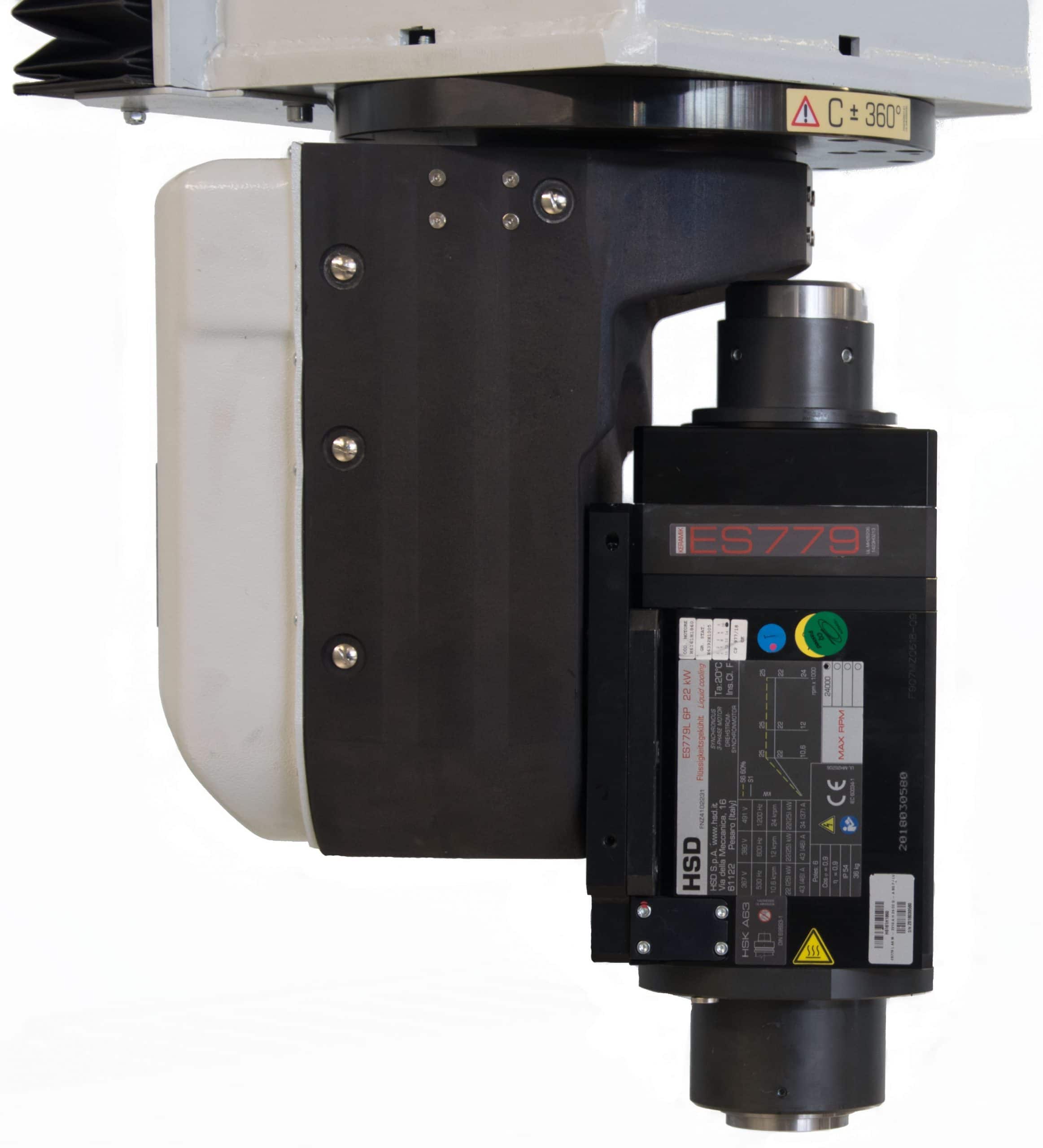

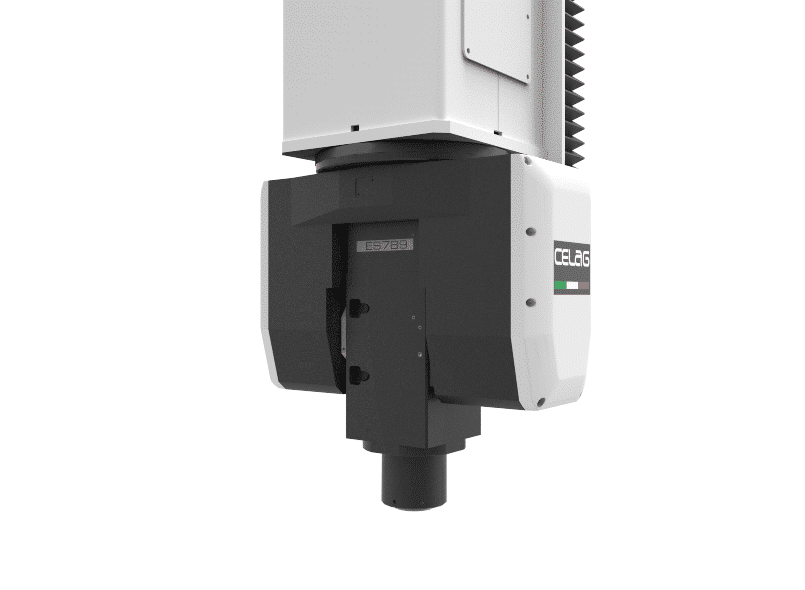

OPERATING UNITS

High torque even at low speed. The HSK interface guarantees torque transmission, speed and precision when changing tools.

| Electro-spindles range | Use |

|---|---|

| Power 10/12 kW Asyn Type HSK F63 Max speed 24.000 rpm Nominal speed 7.500 rpm Liquid cooled |

Suitable for plastics, composites, wood machining |

| Power 15/18 kW Asyn Type HSK F63 / HSK A63 Max speed 24.000 rpm Nominal speed 12.000 rpm Liquid cooled |

Suitable for composites, aluminium machining |

| Power 22/25 kW Synch Type HSK F63 / HSK A63 Max speed 24.000 rpm Nominal speed 10.600 rpm Liquid cooled |

Suitable for composites, aluminium machining |

SUCTION AND CLOSING

Michelangelo Hl with revolving table is equipped with a soundproof cabinet and a powerful suction system that allows you to deal with the work on the most demanding materials such as carbon, ensuring greater cleanliness of the work environment and greater operator safety.

DATA SHEET

| Michelangelo HL | |

|---|---|

| Electrospindle | Power 11/13 kW Power 15/18 kW Power 22/25 kW |

| Axis Range |

X = 4000/5000 Y = 1800/2200/2600mm Z = 1.200mm A = ± 120 ° C = ± 360 ° |

| Rapid Traverse |

X-Y-Z = 80 m/min B/C = 75 °/sec |

| Tool Warehouse |

8-position travelling linear tool warehouse Carousel tool warehouse with 16-positions |

ASK FOR INFORMATION

You might also be interested:

Michelangelo is a range of last generation 5-axis interpolating machining centres, designed to work the most advanced material; composites, special resins, plastics, aluminium, light alloys, wood.

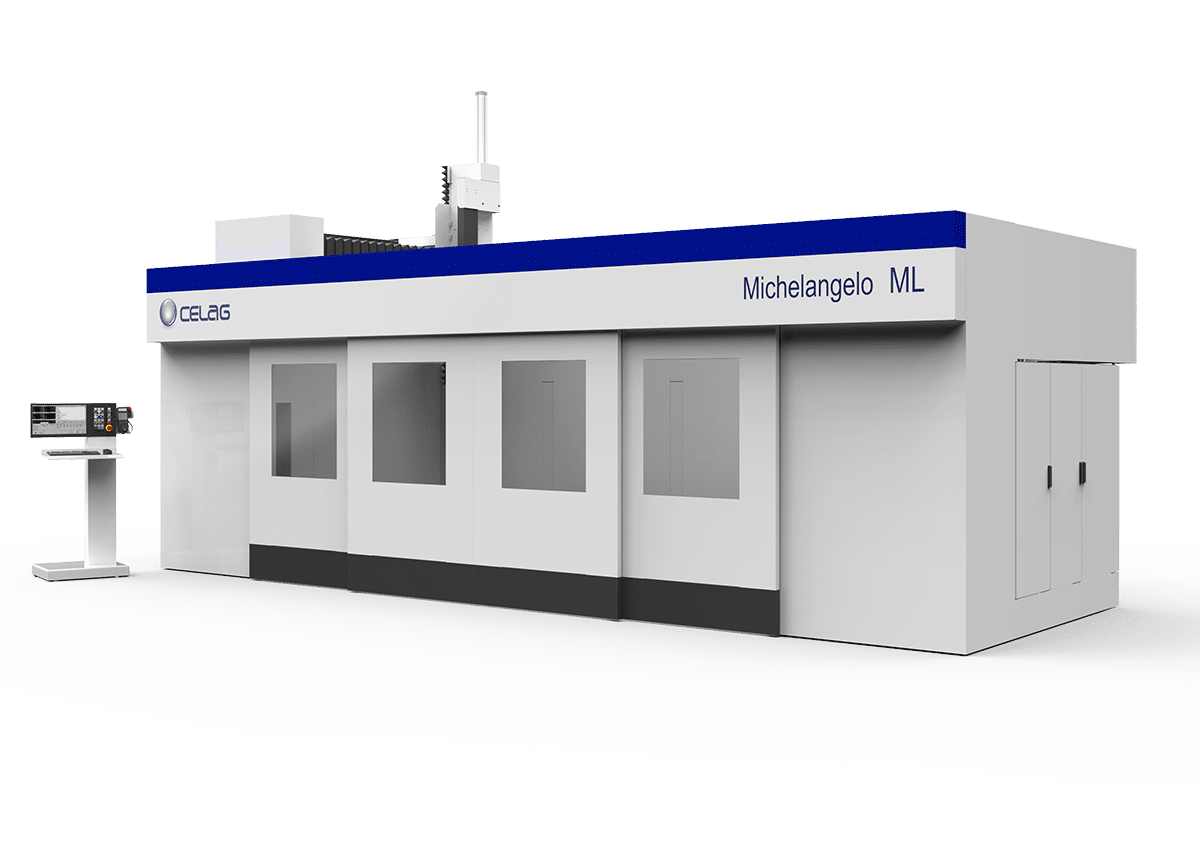

The Michelangelo ML 5-axis machining center is the ideal solution for trimming plastic and composite materials, which thanks to its technical characteristics ensure high productivity and production quality.